Flex Printing Companies in Tirupur

You're looking for flex printing companies in Tirupur, and you'll find plenty of options to choose from. Tirupur's strategic location offers easy access to raw materials and skilled labor, making it an ideal hub for flex printing companies. These companies utilize advanced technologies, including eco-friendly options, to produce high-quality prints at competitive prices. You can expect to find services like digital printing, solvent-based printing, and screen printing, as well as additional services like lamination and cutting. As you explore the flex printing companies in Tirupur, you'll discover the specific benefits and advantages they offer.

Key Takeaways

- Flex printing companies in Tirupur benefit from the city's strategic location, offering access to raw materials, skilled labor, and reduced transportation costs.

- Tirupur is home to numerous flex printing companies that utilize eco-friendly materials and technologies, catering to the growing demand for sustainable printing solutions.

- Top flex printing companies in Tirupur invest in research and development, staying updated with industry trends and technological advancements to provide high-quality services.

- These companies offer a range of printing technologies, including digital printing, solvent printing, and screen printing, to meet specific customer requirements and preferences.

- Flex printing companies in Tirupur provide additional services, such as lamination, cutting, and finishing, to enhance product appearance and durability.

Benefits of Flex Printing

Many flex printing companies can attest to the numerous benefits of flex printing, but what exactly makes this technology so attractive?

As you explore the world of flex printing, you'll discover that it offers a cost-effective solution for advertising needs.

With flex printing, you can produce high-quality prints at a lower cost compared to traditional printing methods. This makes it an ideal choice for businesses looking to promote their brand without breaking the bank.

Another significant advantage of flex printing is its use of eco-friendly materials.

The flex printing process utilizes water-based inks and recyclable materials, reducing the environmental impact of your advertising efforts.

This not only benefits the environment but also enhances your brand's reputation as a responsible and sustainable business.

When you choose flex printing, you're not only getting a cost-effective and eco-friendly solution, but you're also getting a durable and long-lasting product.

Flex prints can withstand various weather conditions and last for an extended period, making them perfect for outdoor advertising.

Types of Flex Printing

You're likely familiar with the benefits of flex printing, but did you know that there are different types of flex printing technologies used by companies today?

Two common types of flex printing are digital flex printing and solvent flex printing, each with its own unique characteristics and applications.

As you explore the world of flex printing, crucial to grasp is understanding the differences between these two types of printing to determine which one best suits your needs.

Digital Flex Printing

Several types of flex printing exist, each with its unique characteristics and applications.

If you're looking for high-quality, photo-realistic prints, digital flex printing is the way to go. This type of printing uses digital mastery to produce vibrant, detailed images on flex materials.

With digital flex printing, you can achieve precise color matching and high-resolution prints that are perfect for signage, banners, and other visual displays.

Digital flex printing is a flex innovation that has revolutionized the printing industry. It uses inkjet technology to print directly onto flex materials, eliminating the need for plates or screens.

This process allows for fast turnaround times, low setup costs, and high-quality prints. Digital flex printing is also an eco-friendly option, as it uses water-based inks and produces minimal waste.

When choosing a digital flex printing service, consider the printer's resolution, ink quality, and material compatibility.

A good digital flex printer should be able to produce prints with a high resolution (at least 720 dpi) and use eco-friendly inks that are compatible with a variety of flex materials.

Solvent Flex Printing

When high-volume printing is required, solvent flex printing is often the preferred choice.

You'll find that this type of printing is widely used for producing large quantities of signs, banners, and other displays. Solvent flex printing uses solvent-based inks that are cured through a heat process, resulting in vibrant colors and durable prints.

As you explore solvent flex printing, you'll need to examine the following key aspects:

- Solvent regulations: Familiarize yourself with local regulations regarding solvent emissions and waste disposal to guarantee compliance.

- Ink formulations: Understand the different types of solvent-based inks available, including eco-solvent and mild-solvent options, to select the best one for your printing needs.

- Printer maintenance: Regularly maintain your solvent flex printer to prevent clogging and guarantee top-notch print quality.

- Environmental impact: Weigh the environmental implications of solvent flex printing and explore options for reducing your ecological footprint.

Flex Printing Process

The flex printing process begins with pre-press preparation, where digital files are created and reviewed to verify accuracy and consistency.

This step is vital in ensuring that the final product meets your requirements. Once the files are ready, you'll move on to the printing stage, where the design is applied to the flex material using a combination of ink and heat.

When it comes to flex signage, you'll typically use a solvent-based ink that's specifically designed for outdoor use.

This type of ink is durable and can withstand various weather conditions. For fabric customization, you may use a different type of ink that's designed for textile printing.

This ink is usually water-based and is gentler on the fabric.

During the printing process, you'll need to adjust the temperature, pressure, and ink flow to achieve the desired results.

The flex material will then be cured in an oven to fix the ink in place.

Top Flex Printing Companies

Across various industries, you'll find numerous flex printing companies that specialize in producing high-quality, customized signs and displays.

As you navigate the flex industry, it's crucial to stay informed about the top companies that are driving innovation and growth. Market competition analysis reveals that these companies aren't only meeting but exceeding customer expectations, setting new standards for the industry.

Some of the top flex printing companies in Tirupur are known for their cutting-edge technology, eco-friendly practices, and exceptional customer service.

They possess a few key characteristics that set them apart:

- Strong emphasis on research and development: These companies invest heavily in R&D, ensuring they stay ahead of the curve with regard to flex industry trends and technological advancements.

- State-of-the-art machinery and equipment: Top flex printing companies utilize the latest machinery and equipment, enabling them to produce high-quality signs and displays efficiently and effectively.

- Focus on sustainability: Many of these companies prioritize eco-friendly practices, using environmentally responsible materials and production methods whenever possible.

- Commitment to customer satisfaction: Top flex printing companies in Tirupur are dedicated to providing exceptional customer service, ensuring that clients receive the best possible experience from start to finish.

Services Offered by Companies

Several top flex printing companies in Tirupur offer a wide range of services to cater to diverse customer needs.

You can expect to find services such as custom solutions, where companies work closely with you to create bespoke flex printing solutions that meet your specific requirements.

These companies also offer a variety of printing technologies, including screen printing, digital printing, and rotogravure printing, allowing you to choose the best option for your product.

In addition to custom solutions, many flex printing companies in Tirupur also offer rush orders, which enable you to get your products printed and delivered quickly.

This is particularly useful if you have a tight deadline to meet or need to respond to changing market conditions.

Some companies also offer additional services such as lamination, cutting, and finishing, which can help to enhance the appearance and durability of your products.

When working with a flex printing company in Tirupur, you can expect a high level of technical expertise and attention to detail.

Many companies have invested heavily in state-of-the-art equipment and technology, ensuring that your products are printed to the highest standards.

Advantages of Tirupur Location

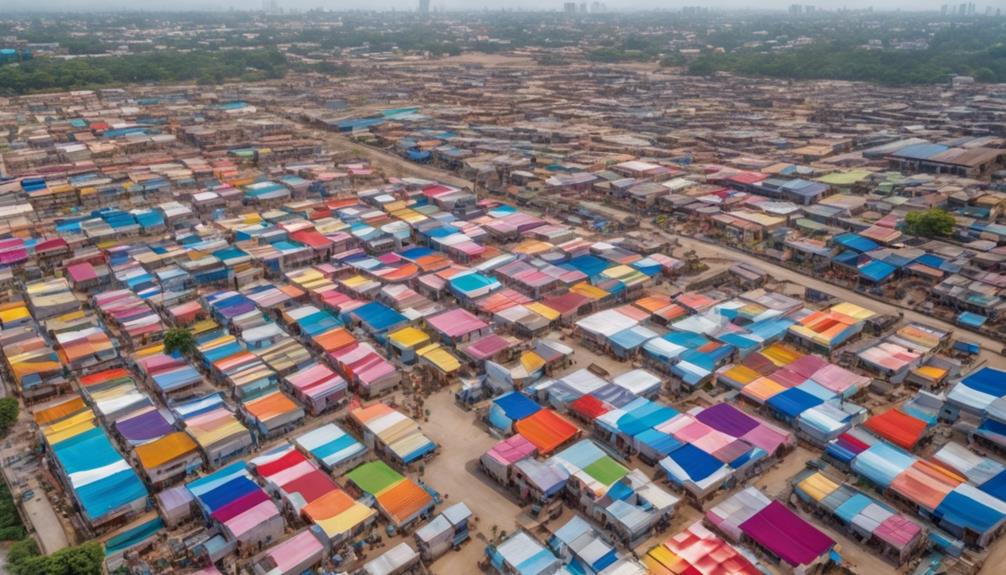

Most notably, Tirupur's strategic location offers numerous advantages for flex printing companies.

As you consider setting up or partnering with a flex printing company in Tirupur, you'll appreciate the benefits of its location.

Tirupur's infrastructure is well-equipped to support the demands of flex printing companies, with access to quality raw materials, skilled labor, and a robust transportation network.

The advantages of Tirupur's location can be summarized as follows:

- *Proximity to textile hubs*: Tirupur is strategically located near major textile hubs, ensuring easy access to raw materials and a steady supply of fabric for printing.

- *Excellent transportation network*: Tirupur is well-connected by road, rail, and air, facilitating the transportation of raw materials, finished goods, and personnel.

- *Skilled labor force*: Tirupur is home to a large pool of skilled labor, reducing recruitment and training costs for flex printing companies.

- *Government support*: The Tirupur infrastructure has been developed with government support, providing a favorable business environment and access to necessary resources.

Flex Printing Technology Used

You'll find that flex printing companies utilize various types of flex printing technologies, including screen printing, rotary printing, and digital printing.

Each of these technologies employs distinct printing process techniques, such as gravure, flexography, and inkjet printing.

Understanding the differences between these technologies and techniques is vital to selecting the right flex printing method for your specific needs.

Types of Flex Printing

Flex printing's versatility has given rise to various printing technologies, each suited to specific applications and industries.

As you explore the world of flex printing, you'll come across different types of printing technologies that cater to diverse needs.

These technologies are designed to work with various flex materials and printing substrates, ensuring that your prints turn out as desired.

Some of the key types of flex printing technologies include:

- Solvent-based printing: This technology uses solvent-based inks to print on flex materials, resulting in vibrant colors and durable prints.

- Eco-solvent printing: A more environmentally friendly option, eco-solvent printing uses gentler inks that are easier on the environment.

- UV printing: This technology uses ultraviolet light to cure the ink, resulting in fast-drying and long-lasting prints.

- Sublimation printing: This process involves printing on heat-sensitive materials, allowing for full-color prints on a variety of substrates.

When choosing a flex printing technology, consider the type of flex material you're working with, the desired print quality, and the intended application.

Printing Process Techniques

Once you've selected a suitable flex printing technology, it's time to weigh the printing process techniques that will bring your design to life.

As a business owner, it's vital to understand the various printing process techniques used in flex printing to guarantee that your products are of high quality and meet your customer's expectations.

Screen printing is a widely used technique in flex printing, where ink is pushed through a mesh screen to create the design.

This technique is ideal for large orders and can produce vibrant colors and detailed designs.

On the other hand, pad printing is a technique that uses a soft silicone pad to transfer ink onto the substrate.

This technique is commonly used for printing on irregularly shaped objects and produces high-quality images.

When choosing a flex printing company, it's imperative to evaluate the printing process techniques they use.

Look for companies that use advanced technology and high-quality ink to guarantee that your products are durable and long-lasting.

Additionally, assess the turnaround time, pricing, and customer service when making your decision.

Quality Control Measures

Implementing effective quality control measures is crucial for flex printing companies to maintain high standards of production.

You need to guarantee that your products meet the required specifications and are free from defects. To achieve this, you should conduct regular material testing to verify the quality of the materials used in the printing process.

This includes checking the ink, fabric, and other supplies for consistency and durability.

In addition to material testing, you should also conduct supply chain checks to guarantee that your suppliers are providing high-quality materials.

This includes verifying the authenticity of the materials, checking for any defects or irregularities, and guaranteeing that the materials meet the required standards.

Some key quality control measures to implement in your flex printing company include:

- Conducting regular inspections of the printing equipment and machinery to guarantee they're in good working condition

- Implementing a system for tracking and recording defects and irregularities

- Providing training to employees on quality control procedures and protocols

- Conducting regular audits to guarantee compliance with quality control standards

Future of Flex Printing Industry

As the demand for flexible and innovative printing solutions continues to grow, the future of the flex printing industry looks increasingly promising.

You can expect to see significant advancements in technology, driving industry growth and shaping market trends.

One key area of development is digital printing, which is becoming increasingly popular due to its high-quality output and fast turnaround times.

You'll also see increased focus on sustainability, with companies investing in eco-friendly printing solutions and materials.

This shift towards environmentally responsible practices is likely to become a major market trend in the coming years.

Additionally, the rise of e-commerce has created a high demand for customized and small-batch printing, which flex printing companies are well-positioned to capitalize on.

As the industry continues to evolve, you can expect to see increased adoption of automation and artificial intelligence, driving efficiency and productivity gains.

With these advancements, the flex printing industry is poised for significant growth and expansion, making it an exciting time for companies looking to invest in this space.

Frequently Asked Questions

What Is the Minimum Order Quantity for Flex Printing?

When considering a printing order, you'll need to know that the minimum order quantity is often determined by the business requirements and production capacity of the printer, typically ranging from 100 to 1,000 units.

Can Flex Printing Be Done on Non-Fabric Materials?

You can explore flex printing on non-fabric materials like paper substrates and rigid plastics. These materials offer unique properties, such as durability and water resistance, making them suitable for various applications, including signage and packaging.

Is Flex Printing Suitable for Outdoor Advertising?

When considering outdoor advertising, you'll want to assess if flex printing can withstand the elements. To guarantee suitability, conduct a durability test to evaluate its weather resistance, as this will impact the material's lifespan and effectiveness.

How Long Does Flex Printing Take to Complete?

When you need flex printing done, production timelines vary, but typical turnaround is 3-7 business days. You can expedite rush orders for an additional fee, cutting production time to as little as 24 hours.

Can Flex Printing Companies Provide Design Services?

You can expect design services from most printing companies, offering design assistance to enhance visual appeal. Their experts will help you create eye-catching designs, ensuring your prints effectively communicate your message and capture your audience's attention.

Conclusion

You've explored the world of flex printing in Tirupur, understanding its benefits, types, and processes. Top companies in the region offer a range of services, leveraging advanced technology and quality control measures. With its strategic location, Tirupur is poised to remain a hub for flex printing. As the industry continues to evolve, you can expect innovations in technology and sustainability, driving growth and efficiency in flex printing. The future looks bright for this sector.